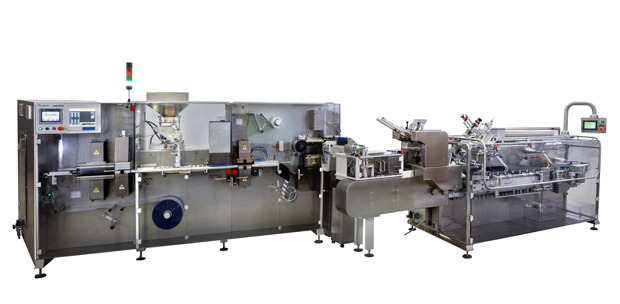

Suitable for medium – high production batches.

Extremely flexible, versatile and simple to operate; Completely flat film flow up to sealing station, and later a multistep cutting process suitable to reach up to 300 blisters /minute; “Balcony type" design to reduce any kind of cross contamination in the working area and have a quick access to all machine features;

Compliance with the GMP standards starting from the design stage; User friendly touch screen with Multilingual commands and eventual PC integration; Including the ability to thermoform any material from the standard PVC, to PVC-PVDC, TRIPLEX, Aclar, PET, ALU-ALU; Very short size change over time: from 15 to 30 minutes for complete size change over tool.

Mechanical speed : up to 50 cycles/minute

Max. Forming area : indexing 155 mm – web width: 230 mm

Max. Forming depth : 13 mm

Production: up to 300 blisters / minute

Download Layout

15 minutes for a partial size change over operation;

30 minutes for a complete size change over operation;

Extreme operational and maintenance simplicity, but highly reliable machine;

Possibility to apply multiple printing units on the machine, for BATCH and EXP, as far for ALU material printing;

Multiple feeding systems at the same time;

Reject control on scrapped units