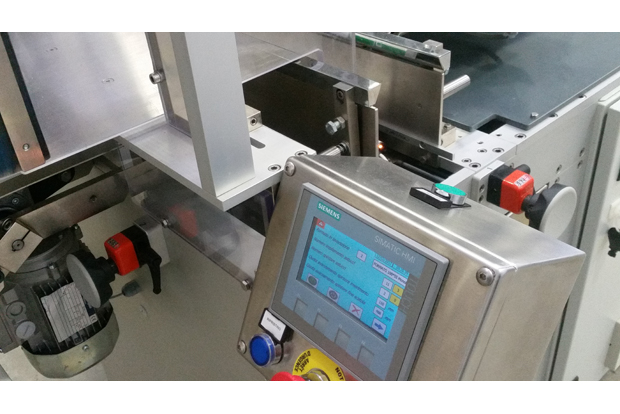

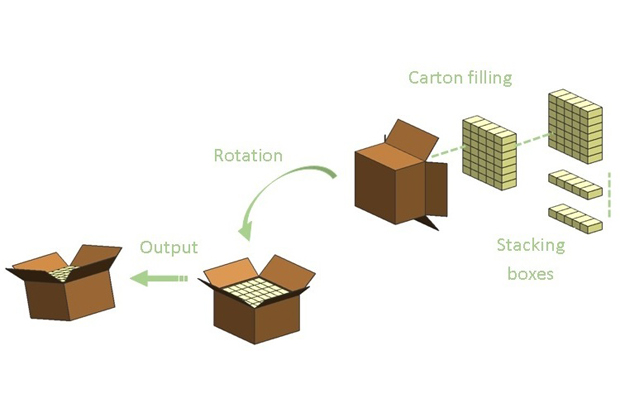

The CM30 side loading case packer has been designed in order to pack boxes in a semi- automatic way. An inlet conveyor belt takes the boxes coming from the cartoning machine, and sends them to the layering device. The boxes are stacked in the requested way before being transferred into the case which has been previously set up. An operator forms the case, and place it around the outer flaps. After complete filling, the case automatically descends until it is placed on the final outlet roller conveyor belt. The case, still opened, can be sent to an outlet conveyor or to an automatic taping machine in order to be sealed. All packaging process is driven from a touch HMI located on the front side of the machine. This packaging machine allows the cartoning machine to run with maximum speed and minimum operator support. Suitable for production batches up to 6 full cartons/ minute. User friendly touch screen with Multilingual commands and eventual PC integration; Exclusive use of electrical motors, without tablet air, in order to have a perfect control of any movement.

Sales informations

10 minutes for a partial size change over operation;

20 minutes for a complete size change over operation;

Simple and reliable machine;

Possibility to apply ink jet printing units for carton marking.

Easy to connect with end of line machines.